Quick Menu

No Sample Conditioning Required

No sample conditioning required for most online Raman measurements

Unlike near infrared (NIR) spectrometry, Raman is not very sensitive to process temperature changes

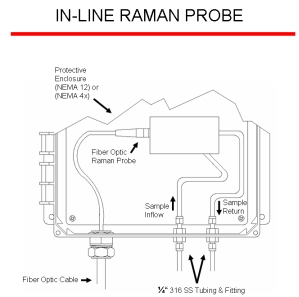

Flow through sample cell configuration

Unlike near infrared (NIR) spectrometry, Raman is not very sensitive to process temperature changes

- Normally does not require sample stream temperature control

- Process stream samples are typically run on lab Raman instrument at room temperature (~ 21°C)

- Chemometric models are then transferred to an online analyzer

- Stream temperature may be > 200°C

- Chemometric models are then transferred to an online analyzer

- Unlike NIR’s strong water absorption, Raman scattering is very weak for water

- No need to remove water via chillers or other water filtration equipment for most online analysis

- Raman is not sensitive to particulates

- Filtration of sample streams is not normally required

- Depending on type of stream, 1 µ filter can be used

- Minimizes flow cell window contamination

- Reduces cleaning requirements

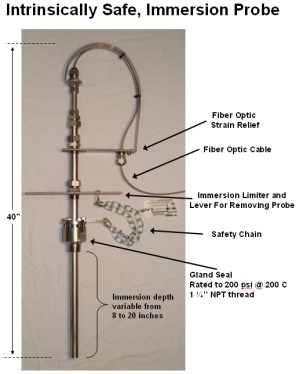

Intrinsically safe, fiber optic coupled remote sampling cells ATEX and IECEx

- Rated for Zone 0

- Uses proprietary Safe-Laser Interlock™ technology

- Fiberoptic cable coupling lengths – up to 1,000 ft (300 m)

- Flow-\ through sample cell

- Rated for

- – 80°C to 250°C

- Up to 3,000 psi (150 bar)

- Rated for

Typical flow cell maintenance requirement – ~ 2 hours/year/probe

- Cleaning of probe flow window requires ~ 5 minutes, typically quarterly or semi-annually

- Eliminates or reduces sample conditioning equipment

- Greatly simplifies Raman equipment installation

- Greatly reduces maintenance costs

- Flow sensors alarm to distributed control system (DCS) for

- No flow condition

- Grab sample collection time

- Standard wettable surfaces – stainless steel grade 316

- Alloy 825, Monel 400, Hastelloy, and other materials – available upon request

Direct insertion probe configuration

- User friendly features allow for direct insertion of our Raman probes into many process streams

- Eliminates need for speed loops and circulation pumps